Automatic Marking and Traceability Systems

- Automotive industry

- Electronics and electrotechnics

- Plastics Industry

- Advertising and Promotional Campaigns

- Pharmaceutical industry

- Mechanical Processing Industry

- Compact Disc production

- Textile industry

- Food industry

Laser marking machines or dot peen marking machines have been integrated on different production lines to automatically inscribe the information necessary to obtain the traceability of the products.

Customised solutions provided:

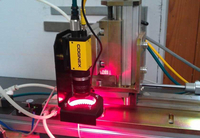

Laser marking 2D codes, reading and software development to create the database – automotive industry

The proposed solution consists in achievement 5 posts that will run operations:

- Marking system laser type FIBER 20W place and fastening device with the ability to track vertical adjustment for precise focusing distance set for all tracks.

- Scanning systems implemented in 4 different positions for reading matrix code marked on the piece.

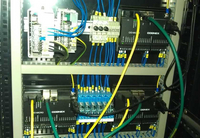

PCs were configured to allow communication with all 5 systems and with existing systems and controls.

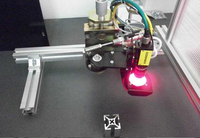

Dot peen marking and matrix code reading – automotive industry

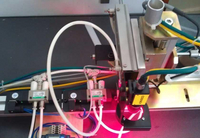

Developed system requires installation of a gravity conveyor marked with pneumatic marking machine and a Cognex reader, type InSight 1110. The operator places the parts on the gravity conveyor so that the pins penetrate the guiding channel system. The presence sensor senses the part in the labeling position and gives the command to start marking matrix codes. After marking the part stops in the reader station and if it notifies no code or the marking is incorrect, the lamp lights a red light signal.

Dot Peen Marking Systems For Flat and Circle Surfaces

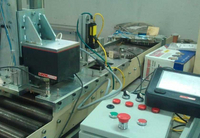

Tensile testing and marking systems

The system consists of a tensile testing machine and, depending on the test result, it is automatically ordered to mark them by micro-percussion by means of a marking machine

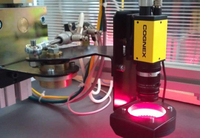

Laser marking 2D code and alphanumeric text on the water meter display

The system is able to mark the 2D code and the other characters on the meter display, after the meter assembly and final test. This means that the laser beam passes directly through the protective glass without damaging it, producing the mark on the display and also not producing emissions to affect the glass.

Laser marking systems for promotional items

The system contains - besides the basic laser marking function - also the programmed options of the Z-axis moving of the marking head, as well as the movement of the parts to be marked under the marking head on the automatic XY axes, depending on the size of the marking, in order to obtain marking on a 400x400mm area

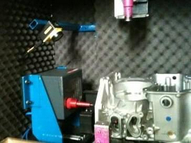

Laser marking systems on gears

The system consists of two main subassemblies; - an embedded laser marking head and a conveyor on which the parts to be marked move. The laser marking head is placed above the conveyor, so that under it, at the required focal length, passes the pieces to be marked. Ten racks are mounted on the conveyor. Each box can accommodate a special box made to allow the parts to be placed in a fixed position, oriented to be marked only in the required position. There are 4 types of such cassettes, 10 pieces for each required area. On each box, depending on the laser marking surface and the diameter of the gears to be marked, a different number of settlement locations will be made so that a maximum number of wheels of a certain type can be entered.

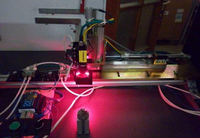

2D code dot peen marking and vision systems

- The marking / reading system of the distribution caps makes the marking of a 2D code on the lids that come on the conveyor, after reading the dot peen code. Diversity is made up of 2 types of pieces.

- The main components of the system are:

- pneumatic stops at the inlet and outlet of the post (non-conforming parts)

- pneumatic cylinder for clamping the part

- pneumatic cylinder for marking the part

- code reading enclosure

- electric control and control panel