Automatic warehouse by BIBUS SES

We innovate we do not imitate!

The innovations in industrial automation have come about after very complex studies in the field. In order to be more efficient, we need to be able to adapt them to customer’s needs.

Below we present a solution to a problem:

• In a production unit with dimensions L / l / H: 50 / 2.7 / 5.3 m, 46 workstations operate daily. Daily 1250 coil feeds power these workstations. The average service time for a coil is 35 s.

• The production company is fully realized by women. Taking into account the dimensions of one coil 0.38 / 0.46 m that can have a maximum weight around 100 kg, we must mention that their loading was made exclusively by women without any automated / mechanized help.

Analysing the real needs of the customer, Bibus Ses has proposed to automates the total production line. Although, perhaps, you can first see the high costs of this investment, but over time, the cost will be amortized by the complexity of the benefits brought to the production:

REDUCTION of storage space by 50%;

Human efforts reduced to MINIMUM;

Increasing the SAFETY and PROTECTION of the employees;

ELIMINATION of human errors;

Increased production quality;

Reduced execution time up to 200%;

PRODUCTIVITY increased with 70%;

Increasing the level of PRECISION and EXECUTION TIME of the production.

- Design / Execution / Installation –

1. Two shelves with a length of 50 m shall be fitted for the 1250 coils;

2. Two manipulators will be used to retrieve the coils from the shelf. Movement control will be done with KOLLMORGEM servo motors with manipulative speeds on axles;

3. 46 rotary plates will be used - one for each workstation - each with 6 controlled positions;

4. Each rotary plate, will be controlled by one operator trough control panels;

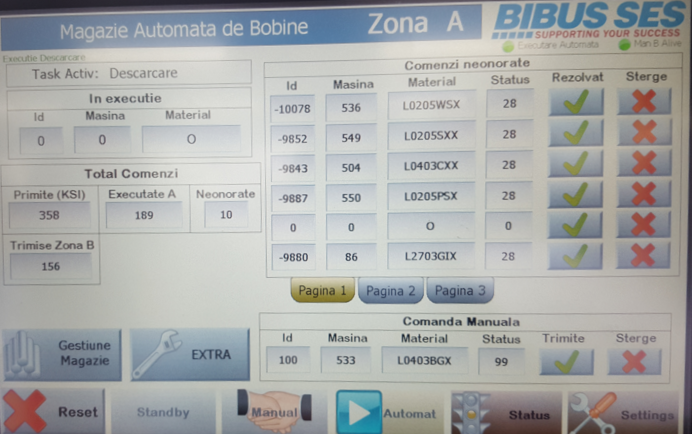

5. There will be 2 main operating panels with HMI for the operators of the automatic warehouse;

6. At the entrance and exit there are 2 charging stations, respectively unloading coils in and from the automatic warehouse.

A well-conducted technical study can lead to many benefits or, on the contrary, a poorly realized study that is not adapted to the client's real needs can lead to a useless investment, the cost of which can no longer be amortized and justified.

Be smart, choose the best!